|

|

|

|

Neodymium Iron Boron Magnets-Ndfeb Magnets

|

|

|

| NdFeB Magnets: The entire title associated with NdFeB magnet is actually Neodymium Metal Boron magnets. It's the 3rd era associated with rare earth magnet and it has already been in a commercial sense obtainable because the middle -1980's. It's the most effective rare earth magnets. These days having higher power item through 8MGOe in order to 52MGOe as well as Neodymium Metal Boron offers great opposition in order to exterior demagnetization areas due to the higher Innate Coercive Pressure (Hci). This particular opposition can make Neodymium magnets wholesale prices a great option with regard to electromechanical programs. Along with plentiful raw materials, NdFeB price much less. Additionally the actual denseness associated with NdFeB items is all about 13% scaled-down compared to SmCo items, simply because NdFeB magnets tend to be more vulnerable to oxidation compared to every other magnetic metal, therefore for many programs, layer or even plating the actual magnets is actually suggested.

|

Sintered NdFeB Magnet |

|

| MAGNETIC CHARACTERISTICS AND PHYSICAL PROPERTIES OF SINTERED NdFeB |

Grade |

Br

mT

(kGs) |

Hcb

kA/m

(kOe) |

Hcj

kA/m

(kOe) |

BH max kJ/m3

(MGOe) |

(Tw) |

N27 |

1030-1080

(10.3-10.8) |

796

( 10.0) |

955

( 12) |

199-231

(25-29) |

80 |

N30 |

1080-1130

(10.8-11.3) |

796

( 10.0) |

955

( 12) |

223-247

(28-31) |

80 |

N33 |

1130-1170

(11.3-11.7) |

836

( 10.5) |

955

( 12) |

247-271

(31-34) |

80 |

N35 |

1170-1220

(11.7-12.2) |

868

( 10.9) |

955

( 12) |

263-287

(33-36) |

80 |

N38 |

1220-1250

(12.2-12.5) |

899

( 11.3) |

955

( 12) |

287-310

(36-39) |

80 |

N40 |

1250-1280

(12.5-12.8) |

907

( 11.4) |

955

( 12) |

302-326

(38-41) |

80 |

N42 |

1280-1320

(12.8-13.2) |

915

( 11.5) |

955

( 12) |

318-342

(40-43) |

80 |

N45 |

1320-1380

(13.2-13.8) |

923

( 11.6) |

955

( 12) |

342-366

(43-46) |

80 |

N48 |

1380-1420

(13.8-14.2) |

923

( 11.6) |

876

( 12) |

366-390

(46-49) |

80 |

N50 |

1400-1450

(14.0-14.5) |

796

( 10.0) |

876

( 11) |

382-406

(48-51) |

60 |

N52 |

1430-1480

(14.3-14.8) |

796

( 10.0) |

876

( 11) |

398-422

(50-53) |

60 |

30M |

1080-1130

(10.8-11.3) |

796

( 10.0) |

1114

( 14) |

223-247

(28-31) |

100 |

33M |

1130-1170

(11.3-11.7) |

836

( 10.5) |

1114

( 14) |

247-263

(31-33) |

100 |

35M |

1170-1220

(11.7-12.2) |

868

( 10.9) |

1114

( 14) |

263-287

(33-36) |

100 |

38M |

1220-1250

(12.2-12.5) |

899

( 11.3) |

1114

( 14) |

287-310

(36-39) |

100 |

40M |

1250-1280

(12.5-12.8) |

923

( 11.6) |

1114

( 14) |

302-326

(38-41) |

100 |

42M |

1280-1320

(12.8-13.2) |

955

( 12.0) |

1114

( 14) |

318-342

(40-43) |

100 |

45M |

1320-1380

(13.2-13.8) |

995

( 12.5) |

1114

( 14) |

342-366

(43-46) |

100 |

48M |

1360-1430

(13.6-14.3) |

1027

( 12.9) |

1114

( 14) |

366-390

(46-49) |

100 |

50M |

1400-1450

(14.0-14.5) |

1033

( 13.0) |

1114

( 14) |

382-406

(48-51) |

100 |

30H |

1080-1130

(10.8-11.3) |

796

( 10.0) |

1353

( 17) |

223-247

(28-31) |

120 |

33H |

1130-1170

(11.3-11.7) |

836

( 10.5) |

1353

( 17) |

247-271

(31-34) |

120 |

35H |

1170-1220

(11.7-12.2) |

868

( 10.9) |

1353

( 17) |

263-287

(33-36) |

120 |

38H |

1220-1250

(12.2-12.5) |

899

( 11.3) |

1353

( 17) |

287-310

(36-39) |

120 |

40H |

1250-1280

(12.5-12.8) |

923

( 11.6) |

1353

( 17) |

302-326

(38-41) |

120 |

42H |

1280-1320

(12.8-13.2) |

955

( 12.0) |

1353

( 17) |

318-342

(40-43) |

120 |

45H |

1300-1360

(13-13.6) |

963

( 12.1) |

1353

( 17) |

326-358

(43-46) |

120 |

48H |

1370-1430

(13.7-14.3) |

995

( 12.5) |

1353

( 17) |

366-390

(46-49) |

120 |

30SH |

1080-1130

(10.8-11.3) |

804

( 10.1) |

1592

( 20) |

223-247

(28-31) |

150 |

33SH |

1130-1170

(11.3-11.7) |

844

( 10.6) |

1592

( 20) |

247-271

(31-34) |

150 |

35SH |

1170-1220

(11.7-12.2) |

876

( 11.0) |

1592

( 20) |

263-287

(33-36) |

150 |

38SH |

1220-1250

(12.2-12.5) |

907

( 11.4) |

1592

( 20) |

287-310

(36-39) |

150 |

40SH |

1240-1280

(12.5-12.8) |

939

( 11.8) |

1592

( 20) |

302-326

(38-41) |

150 |

42SH |

1280-1320

(12.8-13.2) |

987

( 12.4) |

1592

( 20) |

318-342

(40-43) |

150 |

45SH |

1320-1380

(13.2-13.8) |

1003

( 12.6) |

1592

( 20) |

342-366

(43-46) |

150 |

28UH |

1020-1080 (10.2-10.8) |

764

( 9.6) |

1990

( 25) |

207-231

(26-29) |

180 |

30UH |

1080-1130 (10.8-11.3) |

812

( 10.2) |

1990

( 25) |

223-247

(28-31) |

180 |

33UH |

1130-1170

(11.3-11.7) |

852

( 10.7) |

1990

( 25) |

247-271

(31-34) |

180 |

35UH |

1180-1220

(11.8-12.2) |

860

( 10.8) |

1990

( 25) |

263-287

(33-36) |

180 |

38UH |

1220-1250

(12.2-12.5) |

876

( 11.0) |

1990

( 25) |

287-310

(36-39) |

180 |

40UH |

1240-1280

(12.5-12.8) |

899

( 11.3) |

1990

( 25) |

302-326

(38-41) |

180 |

28EH |

1040-1090

(10.4-10.9) |

780

( 9.8) |

2388

( 30) |

207-231

(26-29) |

200 |

30EH |

1080-1130 (10.8-11.3) |

812

( 10.2) |

2388

( 30) |

223-247

(28-31) |

200 |

33EH |

1130-1170

(11.3-11.7) |

836

( 10.5) |

2388

( 30) |

247-271

(31-34) |

200 |

35EH |

1170-1220

(11.7-12.2) |

876

( 11.0) |

2388

( 30) |

263-287

(33-36) |

200 |

38EH |

1220-1250

(12.2-12.5) |

899

( 11.3) |

2388

( 30) |

287-310

(36-39) |

200 |

|

Magnetic characteristics and physical properterties of bonded compression moulding NdFeB magnet |

|

|

Performance |

BNP-6 |

BNP-8L |

BNP-8 |

BNP-8SR |

BNP-8H |

BNP-9 |

BNP-10 |

BNP-11 |

BNP-11L |

BNP-12L |

B r T(Gs) |

0.55-0.62 |

0.60-0.64 |

0.62-0.69 |

0.62-0.66 |

0.61-0.65 |

0.65-0.70 |

0.68-0.72 |

0.70-0.74 |

0.70-0.74 |

0.74-0.80 |

H CB kA/m(kOe) |

285-370 (3.6-4.6) |

360-400 (4.5-5.0) |

385-445 (4.8-5.6) |

410-465 (5.2-5.8) |

410-455 (5.2-5.7) |

400-440 (5.0-5.5) |

420-470 (5.3-5.9) |

445-480 (5.6-6.0) |

400-440 (5.0-5.5) |

420-455 (5.3-5.7) |

H CJ kA/m(kOe) |

600-755 (7.5-9.5) |

715-800 (9-10) |

640-800 (8-10) |

880-1120 (11-14) |

1190-1440 (15-18) |

640-800 (8-10) |

640-800 (8-10) |

680-800 (8.5-10) |

520-640 (6.5-8) |

520-600 (6.5-7.5) |

(BH) max kJ/m 3 (MGOe) |

44-56 5.5-7 |

56-64 7.0-8.0 |

64-72 8.0-9.0 |

64-72 8.0-9.0 |

64-72 8.0-9.0 |

70-76 8.8-9.5 |

76-84 9.5-10.5 |

80-88 10.0-11.0 |

78-84 9.8-10.5 |

84-92 10.5-11.5 |

D g/cm 3 |

5.5-6.1 |

5.6-6.1 |

5.8-6.1 |

5.8-6.1 |

5.9-6.2 |

5.8-6.1 |

5.8-6.1 |

5.8-6.1 |

5.8-6.1 |

5.8-6.1 |

r |

1.15 |

1.15 |

1.15 |

1.13 |

1.15 |

1.22 |

1.22 |

1.22 |

1.26 |

1.26 |

B r %/ |

-0.13 |

-0.13 |

-0.13 |

-0.13 |

-0.07 |

-0.12 |

-0.11 |

-0.11 |

-0.11 |

-0.08 |

T w |

100 |

110 |

120 |

150 |

125 |

120 |

120 |

120 |

110 |

110 |

1.The characteristics in this table are measured on CREM's standard test samples and not guaranteed values. |

2.The above values depend on magnet shape and its dimensions. It is recommended that the figures be certified in actual products. |

|

|

|

|

|

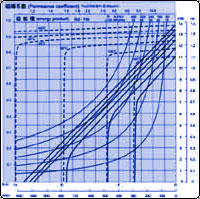

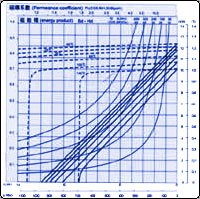

| Demagnetization curves of Sintered NdFeB N40 at different temperature |

Demagnetization curves of Sintered NdFeB N42 at different temperature |

|

|

|

|

|

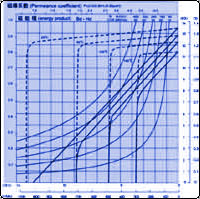

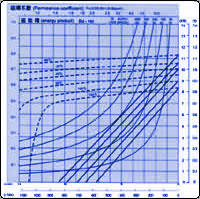

| Demagnetization curves of Sintered NdFeB N33SH at different temperature |

Demagnetization curves of Sintered NdFeB N38SH at different temperature |

|

|

|

|

|

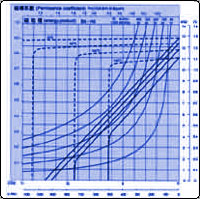

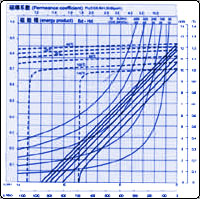

| Demagnetization curves of Sintered NdFeB N30UH at different temperature |

Demagnetization curves of Sintered NdFeB N30SH at different temperature |

|

|

|

|

|

|

E-mail: magnetndfeb@china-ncc.com

Fax: (86)755 26915592

Tel: (86)755 26923096

Online

Order

Address: China Rare Earth Magnet Limited

Room No. 705-707, Tower A Century Holiday Plaza,No.9030 Shennan Rd., OCT, Nanshan District, Shenzhen , China .

Post Code: 518053

|

| |

|

|

|

|

|

Copyright © 2012 China Rare Earth Magnet Limited All Rights Reserved |

|

|

| |

We manufacture Ndfeb magnet, Neo magnet, Permanent Magnet & Rare earth magnet,

sintered NdFeB & bonded NdFeB, Nd-Fe-B magnet & Neodymium magnet,china magnet, china magnets |