Chiny Rare Earth Magnet Co Ltd dostaw spiekany magnes - spiekanych magnesów neodymowych, samar spiekany magnes spiekany magnes alnico & spieku ferrytowego magnes.

|

|

|

| Spiekany magnes: jest jednym z wysokiej wydajności ziem rzadkich magnesy stałe, które wykorzystują neodymowych (ND), żelazo (Fe) oraz boru (B) jako głównych składników i jest podatny na demagnetization gdy narażonych na podwyższone temperatury. Istnieje wiele klas, które mogą wytrzymać wysokie temperatury, ale kilka czynników będzie dyktować wyników działalności magnesem neodymowym. Istnieją Spiekany NdFeB, Spiekany AlNiCo, Spiekany SmCo i Spiekany ferrytowe. |

| Spiekany magnes NdFeB |

|

| WŁAŚCIWOŚCI FIZYCZNE I MAGNETYCZNYCH

WŁAŚCIWOŚCI Spiekany NdFeB |

Stopień |

Br

mT

(kGs) |

Hcb

kA/m

(kOe) |

Hcj

kA/m

(kOe) |

( BH )max kJ/m3

(MGOe) |

(Tw) |

N27 |

1030-1080

(10.3-10.8) |

≥ 796

( ≥ 10.0) |

≥ 955

( ≥ 12) |

199-231

(25-29) |

80 ℃ |

N30 |

1080-1130

(10.8-11.3) |

≥ 796

( ≥ 10.0) |

≥ 955

( ≥ 12) |

223-247

(28-31) |

80 ℃ |

N33 |

1130-1170

(11.3-11.7) |

≥ 836

( ≥ 10.5) |

≥ 955

( ≥ 12) |

247-271

(31-34) |

80 ℃ |

N35 |

1170-1220

(11.7-12.2) |

≥ 868

( ≥ 10.9) |

≥ 955

( ≥ 12) |

263-287

(33-36) |

80 ℃ |

N38 |

1220-1250

(12.2-12.5) |

≥ 899

( ≥ 11.3) |

≥ 955

( ≥ 12) |

287-310

(36-39) |

80 ℃ |

N40 |

1250-1280

(12.5-12.8) |

≥ 907

( ≥ 11.4) |

≥ 955

( ≥ 12) |

302-326

(38-41) |

80 ℃ |

N42 |

1280-1320

(12.8-13.2) |

≥ 915

( ≥ 11.5) |

≥ 955

( ≥ 12) |

318-342

(40-43) |

80 ℃ |

N45 |

1320-1380

(13.2-13.8) |

≥ 923

( ≥ 11.6) |

≥ 955

( ≥ 12) |

342-366

(43-46) |

80 ℃ |

N48 |

1380-1420

(13.8-14.2) |

≥ 923

( ≥ 11.6) |

≥ 876

( ≥ 12) |

366-390

(46-49) |

80 ℃ |

N50 |

1400-1450

(14.0-14.5) |

≥ 796

( ≥ 10.0) |

≥ 876

( ≥ 11) |

382-406

(48-51) |

60 ℃ |

N52 |

1430-1480

(14.3-14.8) |

≥ 796

( ≥ 10.0) |

≥ 876

( ≥ 11) |

398-422

(50-53) |

60 ℃ |

30M |

1080-1130

(10.8-11.3) |

≥ 796

( ≥ 10.0) |

≥ 1114

( ≥ 14) |

223-247

(28-31) |

100 ℃ |

33M |

1130-1170

(11.3-11.7) |

≥ 836

( ≥ 10.5) |

≥ 1114

( ≥ 14) |

247-263

(31-33) |

100 ℃ |

35M |

1170-1220

(11.7-12.2) |

≥ 868

( ≥ 10.9) |

≥ 1114

( ≥ 14) |

263-287

(33-36) |

100 ℃ |

38M |

1220-1250

(12.2-12.5) |

≥ 899

( ≥ 11.3) |

≥ 1114

( ≥ 14) |

287-310

(36-39) |

100 ℃ |

40M |

1250-1280

(12.5-12.8) |

≥ 923

( ≥ 11.6) |

≥ 1114

( ≥ 14) |

302-326

(38-41) |

100 ℃ |

42M |

1280-1320

(12.8-13.2) |

≥ 955

( ≥ 12.0) |

≥ 1114

( ≥ 14) |

318-342

(40-43) |

100 ℃ |

45M |

1320-1380

(13.2-13.8) |

≥ 995

( ≥ 12.5) |

≥ 1114

( ≥ 14) |

342-366

(43-46) |

100 ℃ |

48M |

1360-1430

(13.6-14.3) |

≥ 1027

( ≥ 12.9) |

≥ 1114

( ≥ 14) |

366-390

(46-49) |

100 ℃ |

50M |

1400-1450

(14.0-14.5) |

≥ 1033

( ≥

13.0) |

≥ 1114

( ≥ 14) |

382-406

(48-51) |

100 ℃ |

30H |

1080-1130

(10.8-11.3) |

≥ 796

( ≥ 10.0) |

≥ 1353

( ≥ 17) |

223-247

(28-31) |

120 ℃ |

33H |

1130-1170

(11.3-11.7) |

≥ 836

( ≥ 10.5) |

≥ 1353

( ≥ 17) |

247-271

(31-34) |

120 ℃ |

35H |

1170-1220

(11.7-12.2) |

≥ 868

( ≥ 10.9) |

≥ 1353

( ≥ 17) |

263-287

(33-36) |

120 ℃ |

38H |

1220-1250

(12.2-12.5) |

≥ 899

( ≥ 11.3) |

≥ 1353

( ≥ 17) |

287-310

(36-39) |

120 ℃ |

40H |

1250-1280

(12.5-12.8) |

≥ 923

( ≥ 11.6) |

≥ 1353

( ≥ 17) |

302-326

(38-41) |

120 ℃ |

42H |

1280-1320

(12.8-13.2) |

≥ 955

( ≥ 12.0) |

≥ 1353

( ≥ 17) |

318-342

(40-43) |

120 ℃ |

45H |

1300-1360

(13-13.6) |

≥ 963

( ≥ 12.1) |

≥ 1353

( ≥ 17) |

326-358

(43-46) |

120 ℃ |

48H |

1370-1430

(13.7-14.3) |

≥ 995

( ≥ 12.5) |

≥ 1353

( ≥ 17) |

366-390

(46-49) |

120 ℃ |

30SH |

1080-1130

(10.8-11.3) |

≥ 804

( ≥ 10.1) |

≥ 1592

( ≥ 20) |

223-247

(28-31) |

150 ℃ |

33SH |

1130-1170

(11.3-11.7) |

≥ 844

( ≥ 10.6) |

≥ 1592

( ≥ 20) |

247-271

(31-34) |

150 ℃ |

35SH |

1170-1220

(11.7-12.2) |

≥ 876

( ≥ 11.0) |

≥ 1592

( ≥ 20) |

263-287

(33-36) |

150 ℃ |

38SH |

1220-1250

(12.2-12.5) |

≥ 907

( ≥ 11.4) |

≥ 1592

( ≥ 20) |

287-310

(36-39) |

150 ℃ |

40SH |

1240-1280

(12.5-12.8) |

≥ 939

( ≥ 11.8) |

≥ 1592

( ≥ 20) |

302-326

(38-41) |

150 ℃ |

42SH |

1280-1320

(12.8-13.2) |

≥ 987

( ≥ 12.4) |

≥ 1592

( ≥ 20) |

318-342

(40-43) |

150 ℃ |

45SH |

1320-1380

(13.2-13.8) |

≥ 1003

( ≥

12.6) |

≥ 1592

( ≥ 20) |

342-366

(43-46) |

150 ℃ |

28UH |

1020-1080

(10.2-10.8) |

≥ 764

( ≥ 9.6) |

≥ 1990

( ≥ 25) |

207-231

(26-29) |

180 ℃ |

30UH |

1080-1130

(10.8-11.3) |

≥ 812

( ≥ 10.2) |

≥ 1990

( ≥ 25) |

223-247

(28-31) |

180 ℃ |

33UH |

1130-1170

(11.3-11.7) |

≥ 852

( ≥ 10.7) |

≥ 1990

( ≥ 25) |

247-271

(31-34) |

180 ℃ |

35UH |

1180-1220

(11.8-12.2) |

≥ 860

( ≥ 10.8) |

≥ 1990

( ≥ 25) |

263-287

(33-36) |

180 ℃ |

38UH |

1220-1250

(12.2-12.5) |

≥ 876

( ≥ 11.0) |

≥ 1990

( ≥ 25) |

287-310

(36-39) |

180 ℃ |

40UH |

1240-1280

(12.5-12.8) |

≥ 899

( ≥ 11.3) |

≥ 1990

( ≥ 25) |

302-326

(38-41) |

180 ℃ |

28EH |

1040-1090

(10.4-10.9) |

≥ 780

( ≥ 9.8) |

≥ 2388

( ≥ 30) |

207-231

(26-29) |

200 ℃ |

30EH |

1080-1130

(10.8-11.3) |

≥ 812

( ≥ 10.2) |

≥ 2388

( ≥ 30) |

223-247

(28-31) |

200 ℃ |

33EH |

1130-1170

(11.3-11.7) |

≥ 836

( ≥ 10.5) |

≥ 2388

( ≥ 30) |

247-271

(31-34) |

200 ℃ |

35EH |

1170-1220

(11.7-12.2) |

≥ 876

( ≥ 11.0) |

≥ 2388

( ≥ 30) |

263-287

(33-36) |

200 ℃ |

38EH |

1220-1250

(12.2-12.5) |

≥ 899

( ≥ 11.3) |

≥ 2388

( ≥ 30) |

287-310

(36-39) |

200 ℃ |

|

| Spiekany AlNiCo magnes |

|

| Typowe magnetyczne Performance

do Spiekany AlNiCo magnes |

Stopień |

Br |

Hc |

(BH)max |

Curie Temp. |

Temp.Coe |

US standardowe |

IEC standardowe |

[mT]

[Gs] |

[KA/m]

[Oe] |

[KJ/m3]

[MGOe]] |

[℃] |

[%/℃] |

MMPA

Równoważne |

IEC

Równoważne |

FLN8 |

550

5500 |

42

530 |

9.0

1.13 |

760 |

0.022 |

[S.Alnico 3] |

Alnico 9/3 |

FLNG12 |

700

7000 |

50

620 |

12.4

1.55 |

810 |

0.014 |

S.Alnico 2 |

Alnico 12/6 |

FLNGT18 |

580

5800 |

90

1130 |

18.0

2.20 |

860 |

0.020 |

[S.Alnico 3] |

Alnico 17/9 |

FLNG34 |

1100

11000 |

48

600 |

34.0

4.25 |

890 |

0.016 |

S.Alnico 5 |

Alnico 37/5 |

FLNGT28 |

1000

10000 |

57

710 |

28.0

3.50 |

850 |

0.020 |

S.Alnico 6 |

Alnico 37/5 |

FLNGT38 |

800

8000 |

120

1500 |

38.0

4.75 |

850 |

0.020 |

S.Alnico 8 |

Alnico 36/6 |

FLNGT42 |

880

8800 |

122

1530 |

42.0

5.25 |

850 |

0.020 |

Alnico 38/11 |

FLNGT33J |

700

7000 |

140

1750 |

33.0

4.13 |

860 |

0.020 |

S.Alnico 8HC |

Alnico 36/15 |

|

| Spiekany SmCo

magnes |

|

|

|

Typowe magnetyczne wydajności dla

Spiekany SmCo |

|

| Typowe magnetyczne Performance

do Spiekany SmCo |

Stopień |

Br |

HcB |

HcJ |

(BH)max |

Curie

Temp. |

Temp.Coe |

pracy

T. |

Seria stop |

[mT]

[Gs] |

[KA/m]

[Oe] |

[KA/m]

[Oe] |

[KJ/m3]

[MGOe]] |

[℃] |

[%/℃] |

[℃] |

SmCo18 |

800

8000 |

640

8000 |

1430

18000 |

144

18.0 |

750 |

0.04 |

250 |

1:5 |

SmCo20 |

850

8500 |

640

8000 |

1590

20000 |

160

20.0 |

750 |

0.04 |

250 |

SmCo22 |

900

9000 |

650

8200 |

1430

18000 |

176

22.0 |

750 |

0.04 |

250 |

SmCo24 |

980

9800 |

676

8500 |

1430

18000 |

192

24.0 |

800 |

0.04 |

300 |

2:17 |

SmCo26L |

1050

10500 |

410

5150 |

432

5430 |

208

26.0 |

800 |

0.04 |

300 |

SmCo26 |

1000

10000 |

716

9000 |

1194

15000 |

208

26.0 |

800 |

0.04 |

300 |

SmCo26M |

1000

10000 |

716

9000 |

1590

20000 |

208

26.0 |

800 |

0.04 |

300 |

SmCo28 |

1030

10300 |

760

9500 |

1430

18000 |

224

28.0 |

800 |

0.04 |

300 |

SmCo28H |

1030

10300 |

760

9500 |

1590

20000 |

224

28.0 |

800 |

0.04 |

300 |

SmCo30H |

1100

11000 |

480

6000 |

560

7000 |

240

30.0 |

800 |

0.04 |

300 |

|

| Typowe

Magnetyczne wydajności dla Spiekany ferrytowe

Magnes |

Stopień |

Br |

HcB |

HcJ |

(BH)max |

Curie

Temp. |

Temp.Coe |

IEC

standardowe |

[mT]

[Gs] |

[KA/m]

[Oe] |

[KA/m]

[Oe] |

[KJ/m3]

[MGOe]] |

[℃] |

[%/℃] |

IEC

Równoważne |

Y10T |

200

2000 |

125

1600 |

210

2600 |

6.5

0.80 |

450 |

0.200 |

Ceramic 1 |

Y20 |

360

3600 |

135

1700 |

140

1760 |

20.0

2.50 |

450 |

0.200 |

/ |

Y25 |

380

3800 |

144

1800 |

150

1880 |

24.0

3.00 |

450 |

0.200 |

/ |

Y30 |

390

3900 |

200

2500 |

188

2350 |

27.6

3.40 |

450 |

0.200 |

Ceramic 5 |

Y33 |

410

4100 |

208

2600 |

212

2660 |

30.4

3.80 |

450 |

0.200 |

/ |

Y35 |

415

4150 |

240

3000 |

244

3050 |

31.8

4.00 |

450 |

0.200 |

/ |

Y30BH |

390

3900 |

240

3000 |

256

3200 |

27.6

3.40 |

450 |

0.200 |

Ceramic 8 |

Y33BH |

400

4000 |

240

3000 |

244

3050 |

30.4

3.80 |

450 |

0.200 |

Ceramic 8B |

Y25H |

370

3700 |

264

3300 |

312

3900 |

24.0

3.00 |

450 |

0.200 |

/ |

|

|

|

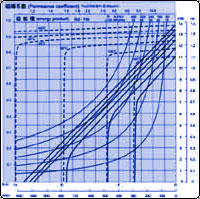

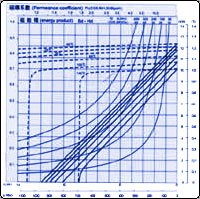

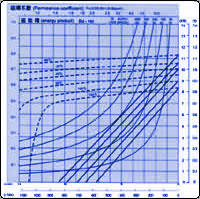

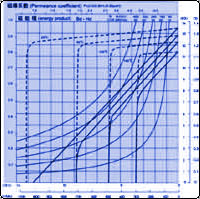

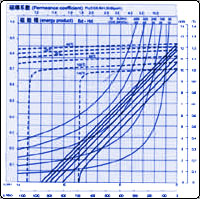

| Demagnetization krzywe Spiekany NdFeB N40 w różnych temperatur |

Demagnetization krzywe Spiekany NdFeB N42 w różnych temperatur |

|

|

|

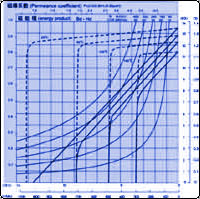

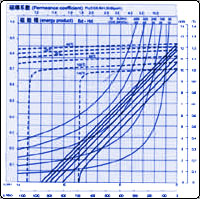

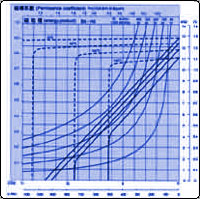

| Demagnetization krzywe Spiekany NdFeB N33SH w różnych temperatur |

Demagnetization krzywe Spiekany NdFeB N38SH w różnych temperatur |

|

|

|

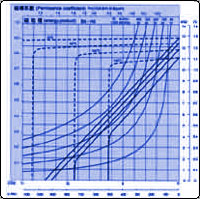

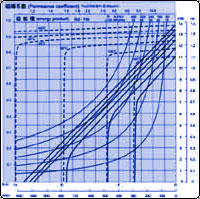

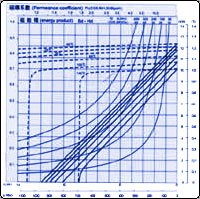

| Demagnetization krzywe Spiekany NdFeB N30UH w różnych temperatur |

Demagnetization krzywe Spiekany NdFeB N30SH w różnych temperatur |

|

|

|

|

E-mail: magnetndfeb@china-ncc.com

Fax: (86)755 26915592

Tel: (86)755 26923096

Online

Order

Address: China Rare Earth Magnet Limited

Room No. 705-707, Tower A Century Holiday Plaza,No.9030 Shennan Rd., OCT, Nanshan District, Shenzhen , China .

Post Code: 518053

|

| |

|

|

|

.gif)

.gif)